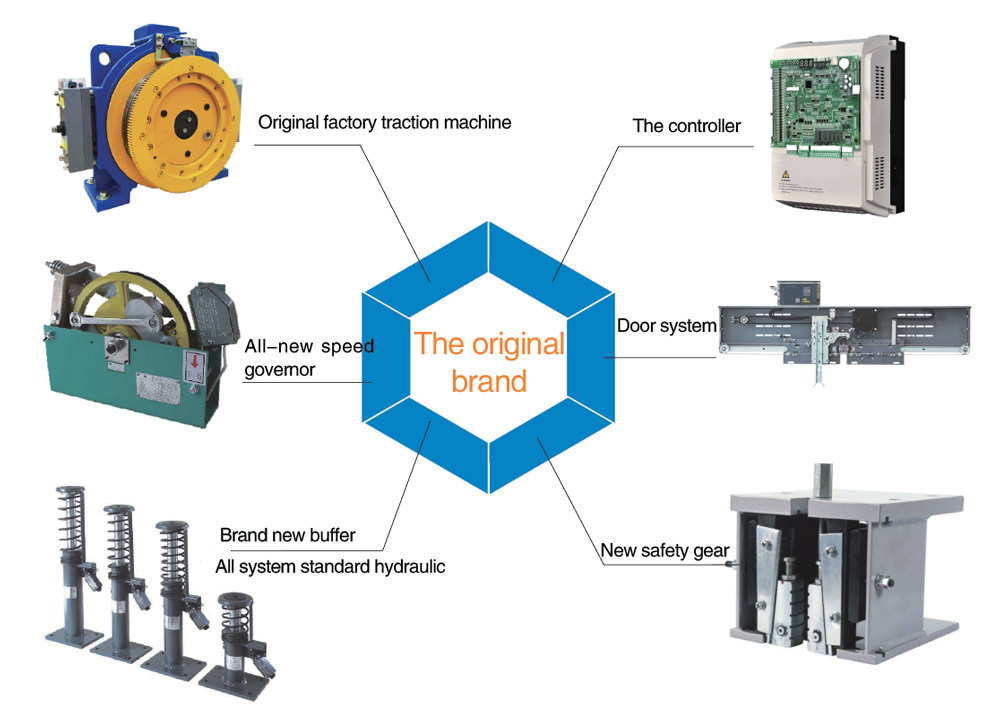

Safe and reliable/energy saving and environmental protection/stable and comfortable/simple and convenient

New and upgraded CHOI ⅢSmall machine room elevator...

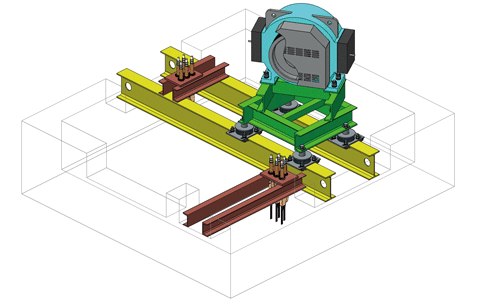

Compact small machine room design

The machine room area is the same as the well area, saving nearly 60% of the room space than the traditional machine room elevator, without taking up more building space, fully improving the utilization of the building, reducing the cost of real estate development.

Ultra-thin control cabinet

Thin control cabinet independently developed and designed by BLT use mature integrated circuit Yuanda technology, improve the anti-interference ability, reduce wiring, and reduce the thickness of the control cabinet, so as to effectively improve the utilization rate of the room space.

Product family expansion

The load is expanded to 1600kg, the number of passengers is increased to 21, the new control system, driving parts, structural design, from the details to ensure the stable operation of the elevator

Elevator control section:

(1) The indoor display adopts LED or LIQUID crystal display, with zero radiation, low power consumption, small heat dissipation, clear floor display image and novel vision;

(2) Ultra-thin wall-mounted call box is adopted outside the hall door for easy installation;

(3) The brake adopts induction coil energy-saving step-down control mode, which is more green and energy-saving, reduces heat and improves working stability;

(4) Safety protection broken line detection function is adopted to avoid alarm missing phenomenon caused by broken line;

(5) The elevator adopts MPDK series control and drive system, and adopts dual 32-bit processing chips to concentrate the functions of the elevator controller and high-performance vector frequency converter, which is the core of an elevator drive and control system:

Advanced technology:

The system perfectly integrates the industrial bus technology into the elevator control, which makes the elevator run more safely, accurately and quickly.

It is distributed in each part of the elevator microprocessor, flexible and precise control of the elevator each part of the action.

Precise control:

The optimal speed change curve output by the precise calculation of the control system is perfectly applied in the operation of the elevator, which eliminates the discomfort of taking the elevator and makes the speed change occur unconsciously when the elevator starts, runs and stops.

High reliability:

Mature industrial bus technology and SMT surface mount technology reduce the volume and weight of the product, improve the anti-interference and anti-vibration capability of the machine, and ensure the reliable operation of the system.

Easy handling:

Good man-machine interface makes debugging and configuration extremely simple, greatly meet the changing requirements of buildings and passengers;

Multi-category fault handling, detailed fault recording information, accurate historical data storage, can enable you to get accurate elevator fault information data.

People first:

With the Internet of things (remote monitoring, residential monitoring), wireless interphone and other functions, reduce the additional harm brought by the elevator trapped people.

(6) The selection of the world famous low-voltage electrical products manufacturers, prolong the electrical life of the system and ensure the reliability of the work;

(7) The end station adopts software and hardware dual redundancy protection, so that the elevator operation is more safe and reliable.

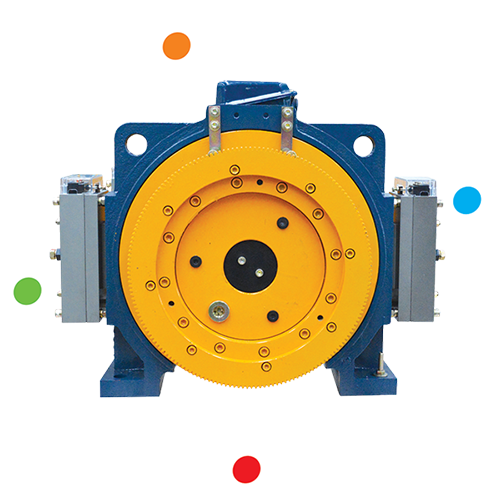

The rotor is composed of high performance permanent magnets and has no excitation current, which greatly improves the operation efficiency and reduces the energy consumption by about 40%

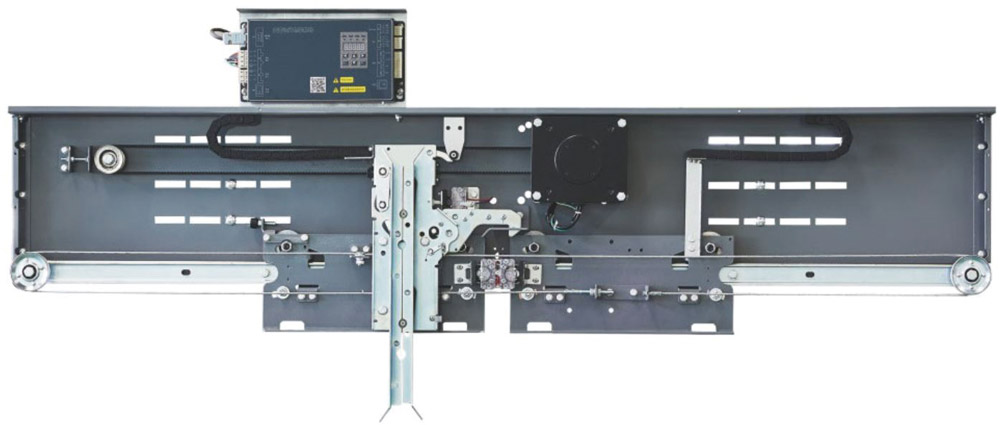

(1) Using permanent magnet synchronous motor frequency conversion drive door machine system, with low speed, high efficiency, constant torque, high control accuracy, low noise, small vibration, maintenance free and other characteristics;

(2) The door motor adopts horizontal permanent magnet synchronous motor, which has the characteristics of compact structure, low speed, large torque, high efficiency, low operating noise, small vibration and long service life;

(3) HTD5M arc tooth synchronous belt drive, bandwidth 15mm, with high transmission efficiency, smooth transmission, high transmission accuracy, low noise, simple structure characteristics;

(4) The use of upper and lower holding devices to prevent the door from separating from the guide device, to avoid the danger of falling into the well for human reasons;

(5) Door safety protection device, adopt advanced light curtain, open and close the whole cross light scanning, without external controller, with good electromagnetic compatibility and anti-light interference;

(6) The synchronous door knife with integrated door lock function is adopted to prevent from falling into the well, and the synchronously opening and closing of hall and car door is truly realized;

(7) More than 8 million times of opening and closing tests and hall door system impact test certification, to ensure the safety, stable and reliable operation of the elevator door system.

采用永磁同步无齿轮曳引机,将同轴传动技术、数字变频技术和群组电脑组合控制技术充分融合,运行成本小,能量失散低,比一般传统技术可节省能源33%以上。无齿轮曳引机无需更换油脂,无油渍污染,低噪音。

(1) 测量系统与变频器相互兼容,给系统以最优的配置;

(2) 配置电机过热保护功能,开闸检测功能,达到更安全有效的运行;

(3) 配有手动盘车装置,为营救乘客提供了必要的途径。

(1) This product contains two kinds car of clear height of 2320mm and 2450mm, beautiful and durable.

(2) LED car lighting, high energy saving, long life, environmental protection, low maintenance cost;

(3) Multiple shock absorption design, with elastic rolling guide shoes, minimize the impact of the source on the car, more comfortable and stable;

(4) Integrated welding for CWT frame, convenient installation, safe use;

(5) Modular installation design idea to reduce installation labor intensity, improve installation efficiency;

(6) Self-reset safety gear, reduce the labor time of maintenance personnel and the possibility of danger;

(7) Parametric design of the whole process, automatic operation of the system, non-standard is easier.

○Standard LED lighting system, safe, efficient, energy saving, easy maintenance.

○Vibration resistance, impact resistance, especially suitable for elevator sports products lighting.

○The actual life can reach more than 50,000 hours.

English

English  简体中文(中国)

简体中文(中国)  Español

Español  Русский

Русский